|

KILN DEVELOPMENT

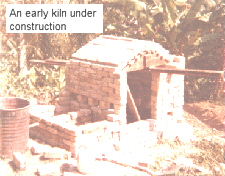

Between the time we started and the mid-eighties

we had built several small kilns. Each kiln was an improvement on the one before

as we struggled to create a kiln design which was inexpensive, even firing, fuel

efficient and easier to manage than the one before.

When we had a design to reasonably fill

the requirements we decided to build it on a larger scale ( 216 cu ft) to

accommodate more pieces. Since then we realised that a bigger kiln is not always

the answer to efficiency as prompt response to small orders requires a speedy

turn around that is only possible in a small kiln. When we had a design to reasonably fill

the requirements we decided to build it on a larger scale ( 216 cu ft) to

accommodate more pieces. Since then we realised that a bigger kiln is not always

the answer to efficiency as prompt response to small orders requires a speedy

turn around that is only possible in a small kiln.

All our kilns were built with recycled firebricks purchased inexpensively

from the Bauxite or Glass Company. The first kiln was designed to fire with wood

then we added an oil burner. In those days we did a bisc firing and the next

kiln had a large firebox area for wood to bisc as well as oil burners for the

glaze firing. We fired this way for a number of years using wood to start the

firing and oil to complete it. We discontinued the use of wood with regret as it was time consuming and

labour intensive in favour of gas that costs more but is easier to work with and

a more efficient fuel. The gas started the firing and when the kiln was hot

enough, about 1000 degrees C, the oil would be introduced. We built a larger

kiln in the early 1990s that was fired with kerosene or diesel oil from a

vaporizer heated by gas burners. At about the same time we were raw glazing

eliminating the bisc firing or reserving it for larger pieces for safety during

the glazing process. |

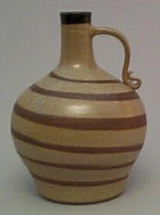

This method of firing resulted in ash falls from

the wood creating interesting effects on pieces left unglazed to take advantage

of the effects. (see bottle by Belva to the left)

This method of firing resulted in ash falls from

the wood creating interesting effects on pieces left unglazed to take advantage

of the effects. (see bottle by Belva to the left)

Raw glazing improved our efficiency by condensing two

firings into one thereby reducing total firing time and eliminating one set of

packing and unpacking In the mid nineties the Government removed the subsidies

from kerosene sending up the cost of the oil. We discontinued the use of the big kiln as

a kiln built from hard firebricks that absorb a tremendous amount of the heat

generated is too expensive to fire with gas. Our kiln furniture had also

deteriorated. Plans for the future included either dismantling that kiln and

building another or lining with insulating bricks and rebuilding the roof with

ceramic fiber and insulating bricks. At that time we were firing entirely with

gas in a small kiln. The big kiln was dismantled and

Raw glazing improved our efficiency by condensing two

firings into one thereby reducing total firing time and eliminating one set of

packing and unpacking In the mid nineties the Government removed the subsidies

from kerosene sending up the cost of the oil. We discontinued the use of the big kiln as

a kiln built from hard firebricks that absorb a tremendous amount of the heat

generated is too expensive to fire with gas. Our kiln furniture had also

deteriorated. Plans for the future included either dismantling that kiln and

building another or lining with insulating bricks and rebuilding the roof with

ceramic fiber and insulating bricks. At that time we were firing entirely with

gas in a small kiln. The big kiln was dismantled and  a new kiln built in its place. We have been firing with gas only, since the nineties but this year 2005 we have begun to fire the newest kiln with gas and deisel oil as the cost of gas has increased considerably making oil again worth considering. The oil system has been upgraded with redesigned burners to burn the heavier deisel oil. We hope to recapture the fired effects which we had in the eighties and nineties.

a new kiln built in its place. We have been firing with gas only, since the nineties but this year 2005 we have begun to fire the newest kiln with gas and deisel oil as the cost of gas has increased considerably making oil again worth considering. The oil system has been upgraded with redesigned burners to burn the heavier deisel oil. We hope to recapture the fired effects which we had in the eighties and nineties.